Clean cookstoves for malawi

COOKs SMOKELESSLY

recycles farm waste

preserves forests

Roles: Product Manager, Mechanical Engineer

SKILLS

Product Management

Prototyping

User Interviews

Research

Scientific Communication

Situation

Our Action

Result

1. Malawian farms generate crop waste.

Often, it just rots or burns.

2. Traditional cookstoves emit smoke.

This has serious health consequences.

3. Electrification is not universal, and gas stoves have unreliable fuel supplies.

Design a stove that makes use of farm waste, based on interviews with Malawian villagers.

Engineered a smokeless cookstove that uses corn cobs as fuel, makes charcoal as a byproduct, and costs less than $5 USD in materials.

WHAT WE MADE

Smokeless stove prototype, built with Malawian materials. Boils water in under 10 minutes.

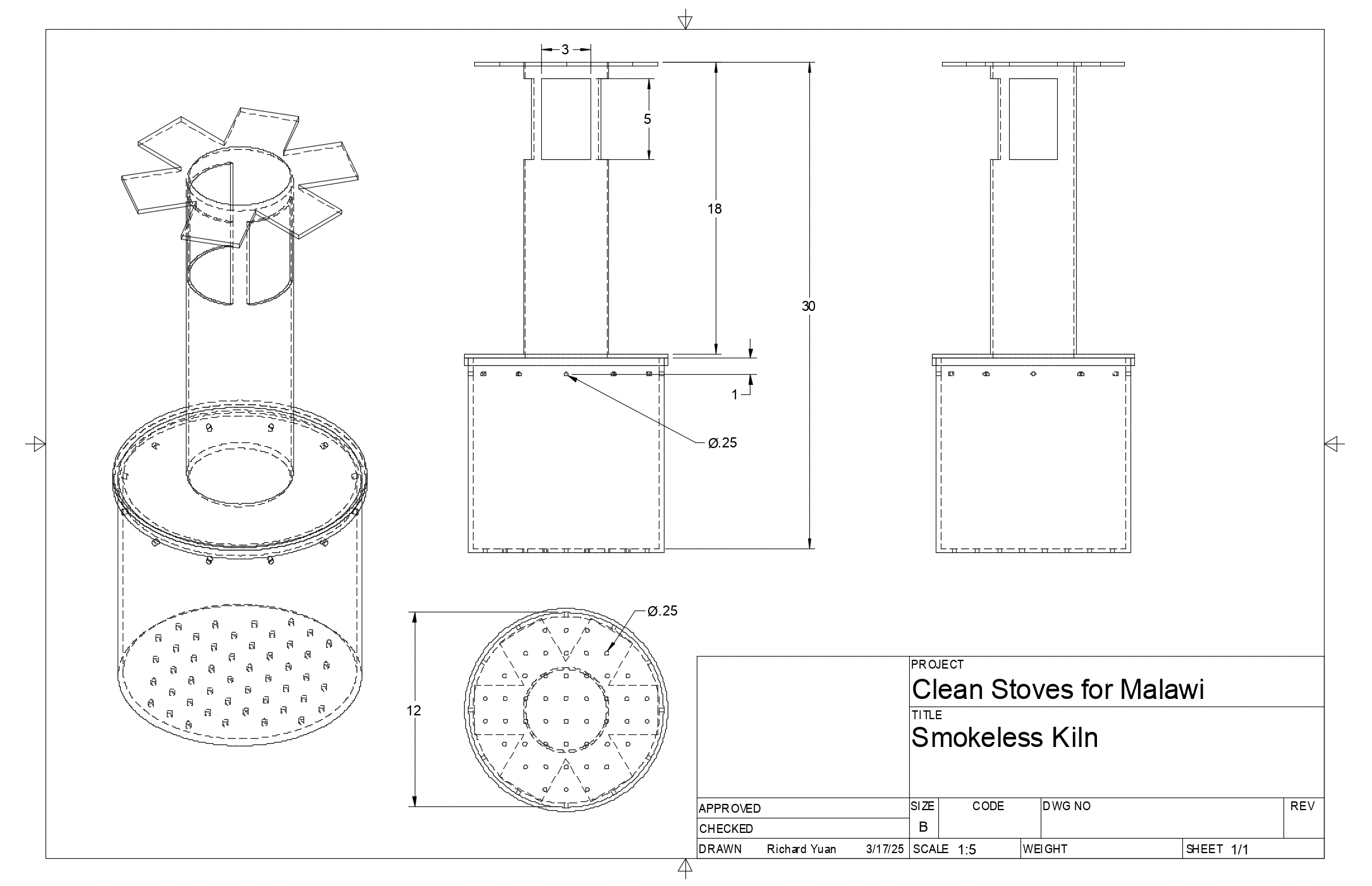

A dimensioned engineering drawing of our design.

3D render (Fusion 360)

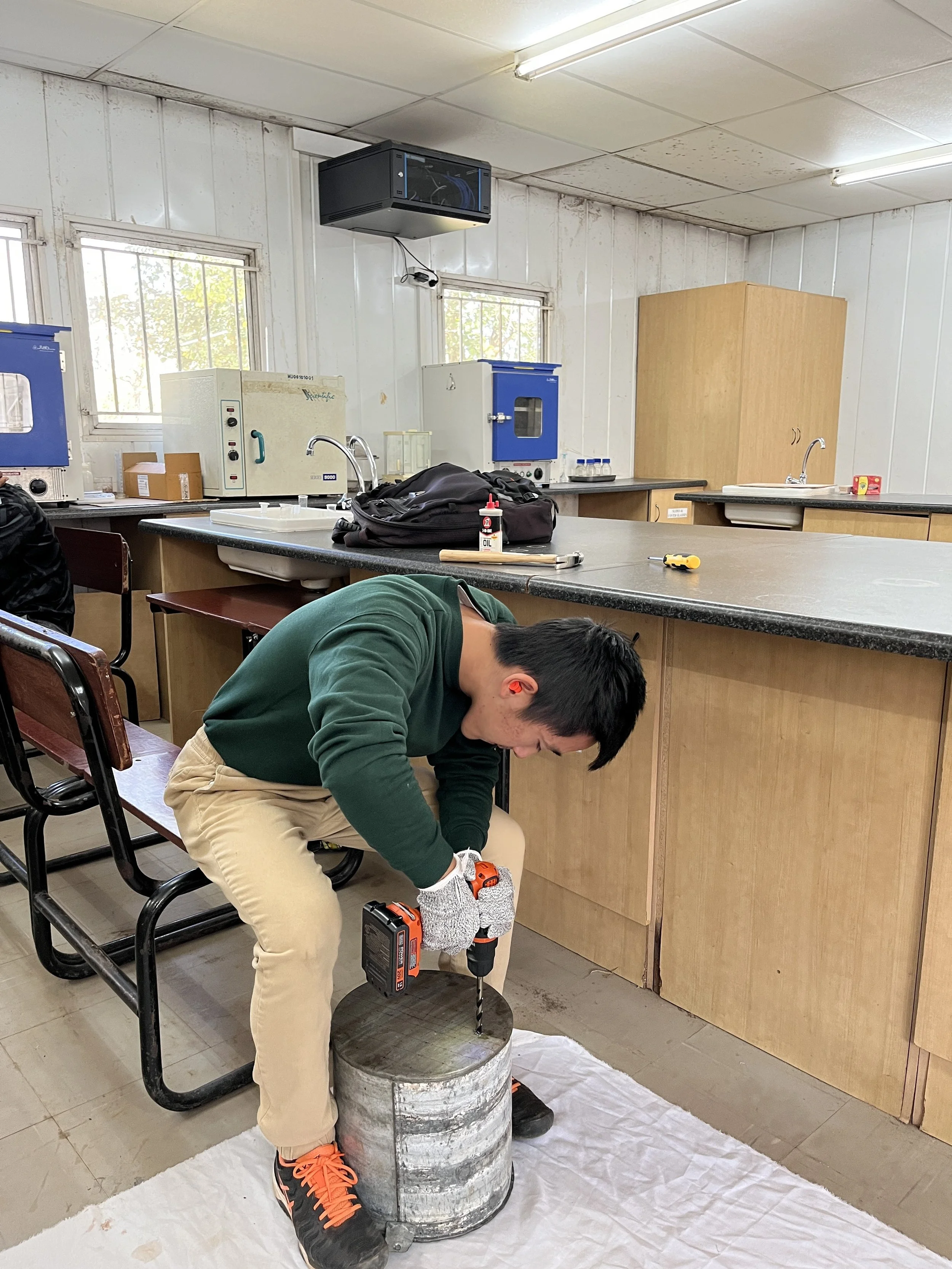

The Story

It began with a call.

We built trust with the Wildlife Environmental Society of Malawi (WESM) by talking over Zoom to understand the problem at hand.

They told us that leftovers from agricultural harvests cause pollution. Since there is no waste management system, Malawians simply burn the waste, putting smoke into the air they breathe.

We also learned that deforestation is rampant in Malawi, since people burn wood to cook.

We spent 10 weeks designing, building, and testing prototype stoves.

As project manager, I outlined timelines and deliverables, as well as taught my teammates how to operate machinery safely.

Then we did our own scientific research.

We produced a 20-page literature review, a research poster, and a list of technical requirements that our solution had to meet.

Our research led us to one key question:

What if we could build a stove that uses farm waste as fuel, instead of wood?

We ended up with a prototype that wasn’t entirely functional, but had promise.

Enough promise to continue our work in person. In Malawi.

ONE 24-HOUR FLIGHT LATER…

We were greeted by our Malawian colleagues, Dr. Tandwe and Mr. Ngonga. They became our mentors and good friends.

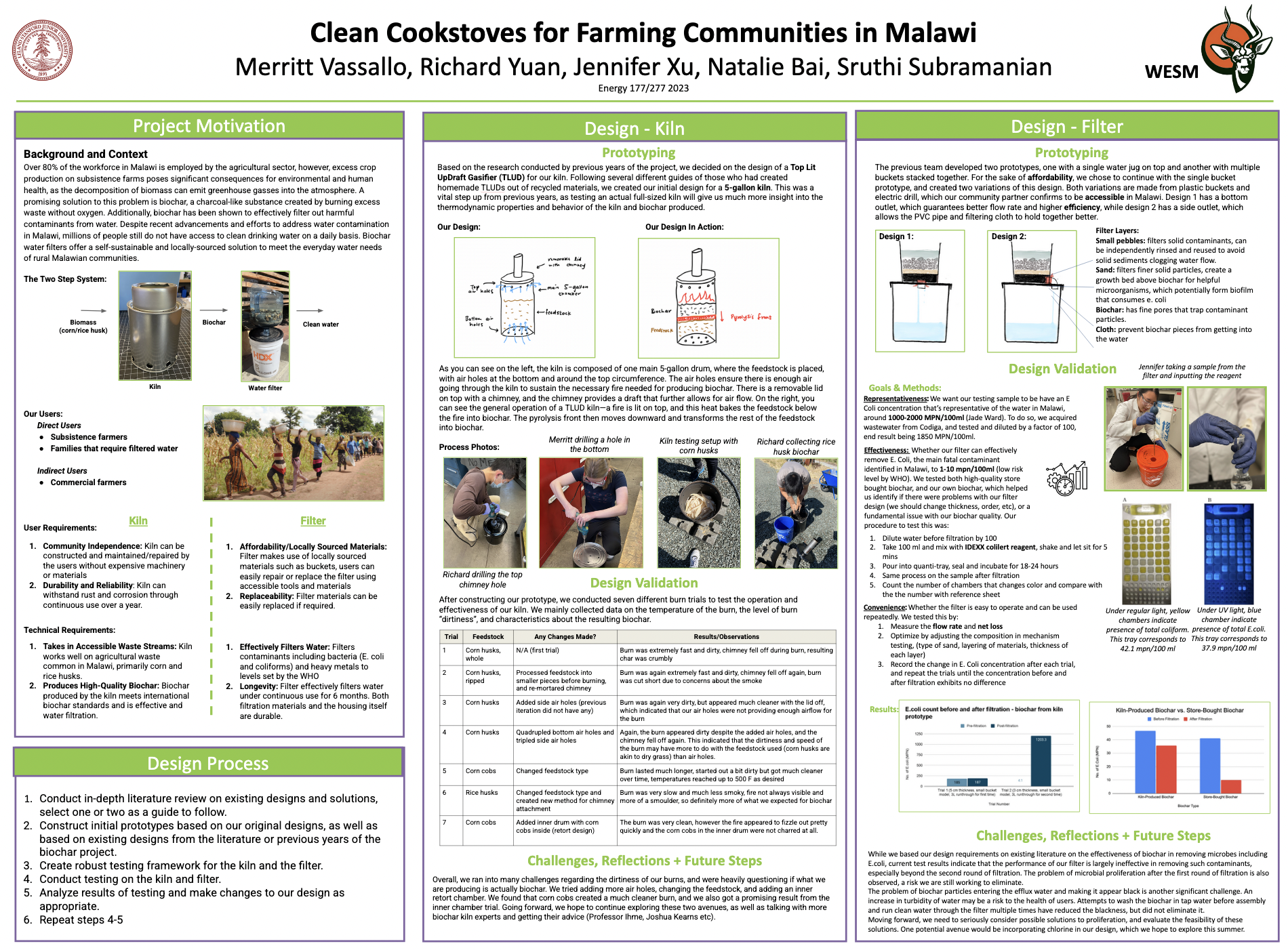

We adjusted our designs to fit our new work environment. Materials were limited, and we no longer had access to heavy machinery - only hand tools.

The “pot stand” design, as it came to be called, could boil water in under 10 minutes and produce charcoal as a byproduct.

Charcoal is a popular cooking fuel in Malawi. This made our stove even more appealing to Malawian users.

It’s also an alternative to wood, so by creating it, our stove could help avoid deforestation.

After recovering from our jet lag, we searched local markets for supplies to replicate our prototypes.

Under my continued project management, and with help from students of Mzuzu University, we successfully replicated our prototype.

This time, it worked.

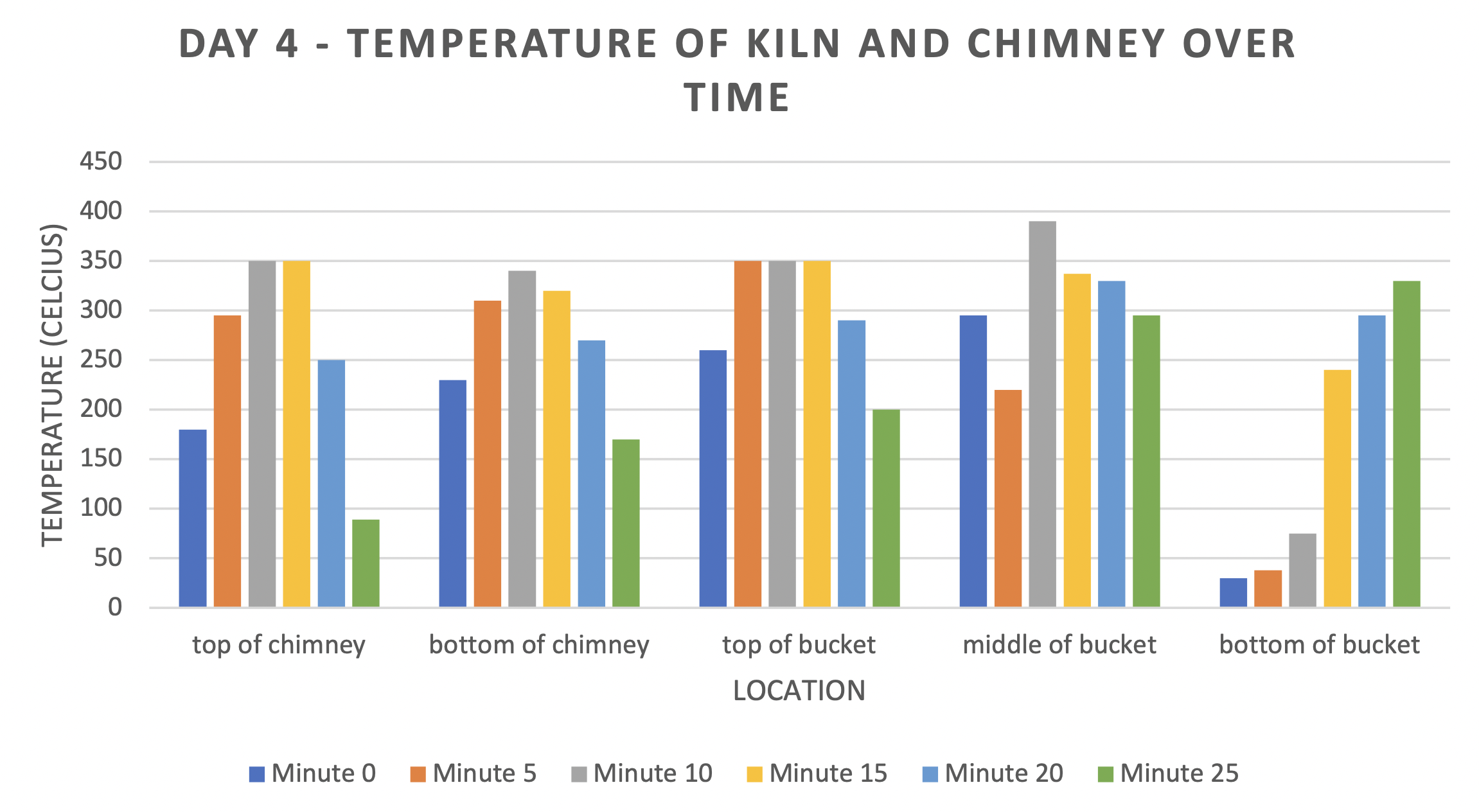

We did a series of controlled burn tests to see whether design tweaks or different environments would affect the stove’s performance.

Using this data, we refined the number of holes and the chimney height.

With our revised designs, we went to 2 rural Malawian villages and demonstrated our stoves. Then, we conducted 20+ interviews with villagers to gauge their opinions about it.

By letting the villagers guide our design process, we discovered further design improvements to make. Like having an integrated pot stand.

Our final act was to write a 60-page report, documenting all that we learned. Everything from instructions on how to build the stove, to insights from our village interviews.

To this day, our report is still used by Stanford students to continue our work.

Thank you, Malawi!